PRODUCT Detail

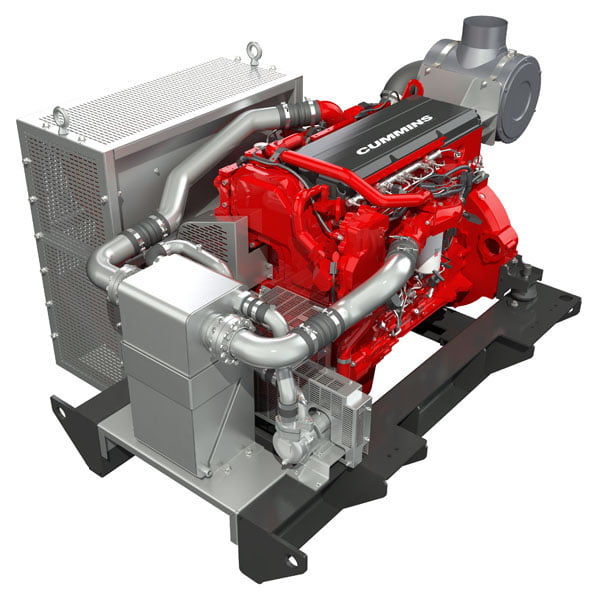

Designed and tested based on Inland Waterway customer requirements, the X15 Stage V is certified to the latest emission standard and able to deliver optimum performance and efficiency.

This integrated engine and aftertreatment package was developed in-house for key European Inland Waterways applications including bow thrusters and main propulsion.

<!–*/<!–*/<!–*/*//*–>*//*–>*//*–>*/

Side mounted

Top mounted

General specifications

| Engine type | X15 Stage V |

|---|---|

| Configuration | In-line, 6 cylinder, 4-stroke diesel |

| Aspiration | Turbocharged |

| Displacement | 14.9 L |

| Bore and Stroke | 137 mm x 169 mm |

| Fuel system | Cummins XPI |

Product dimensions

Side mounted

| Length mm (in) | Width mm (in) | Height mm (in) | Weight kg (lb) |

|---|---|---|---|

| 2428.1 (95.6) | 1856 (73.1) | 1466.6 (57.7) | 2400 (5291.1) |

Top mounted

| Length mm (in) | Width mm (in) | Height mm (in) | Weight kg (lb) |

|---|---|---|---|

| 2428.1 (95.6) | 1384.3 (54.5) | 1921.1 (75.6) | 2500 (5511.6) |

Custom options

Flexible aftertreatment mounting options include side and top mounted, to better accommodate for existing vessel engine room space.

Features

- Cummins engine — Cummins 15 liter is a proven engine in multiple global applications. The engine along with the aftertreatment is fine-tuned to deliver maximum efficiency, productivity, reliability and uptime.

- Turbocharger — Cummins award-winning VGT™ Turbocharger sets the industry standard for reliability and durability, providing long lasting and trouble-free performance.

- Fuel system — Cummins XPI fuel system delivers a precise quantity of fuel at ultra-high pressures. With robust electronic engine controls, it enables flexibility in injection timing to maximize fuel economy and performance while minimizing exhaust emissions.

- Aftertreatment — The Diesel Oxidation Catalyst (DOC), Selective Catalytic Reduction (SCR) and a Diesel Particulate Filter (DPF) are all proven technologies. The solution offers good accessibility to perform service and maintenance.

- Control and monitoring — C Command Elite Plus offers additional functionality and monitoring with the added benefit of an easy-to-read and customer configured color display.

- Warranty and service — Supported by a global standard Cummins factory warranty and supported by a robust dealer network in Europe.

Standard equipment

Mounting

- Engine flexible mounted on skid with top or side aftertreatment configuration

Filtration

- Cummins spin-on oil filters available for easy accessibility and servicing

- Fleetguard® fuel filters with NanoNet® Advanced Media provide up to 13 times greater protection against particles 4 microns and larger

Electronics

- Fully Integrated Electronic Controls offer a single higher capacity Electronic Control Module (ECM) to control everything from air intake to exhaust aftertreatment, for peak performance and near-zero emissions

Cooling System

- Two-pump, two-loop system, low temperature aftercooling with frame mounted charge air cooler maximizes efficiency and improves performance

Aftertreatment

Cooled Exhaust Gas Recirculation (EGR) lowers combustion temperatures for reduced emissions and optimized fuel efficiency. This next-generation system has been rebalanced for use with SCR, reducing flow volume and minimizing Diesel Exhaust Fluid (DEF) consumption levels.

- Cummins Diesel Particulate Filter (DPF) system with active regeneration requires less than 1 percent of operating time and has no impact on equipment operation

- Cummins Selective Catalytic Reduction (SCR)

- Diesel Exhaust Fluid (DEF) dosing system integrated on the skid

- DEF tank option available

Control and monitoring system

C Command Elite Plus system is a type approved system designed for marine applications. The system consists of a cabinet with full color display, emergency stop button, integrated sensors and alarm switches. The easy to control display is configurable for flexible data presentation. The information displayed by the panels provides insight into engine operating conditions such as engine load, fuel consumption, running hours, temperatures and pressure.

Customer Interface Box

- Integrated control panel

- Full color text and graphics in menu format

- Multiple languages and configurations

- Stores a comprehensive history of alarms and faults for more efficient trouble shooting and service scheduling

- Capable of supporting customer-supplied temperature, pressure and switch inputs

Remote Panel (optional)

- 8.4” color touchscreen panel with a high resolution screen. Configurable touch screen features superior visibility even in direct sunlight

- Capable of simultaneously monitoring and controlling up to eight engines

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ