PRODUCT Detail

SmartEfficiency: High-Achieve and Cost-Lowering

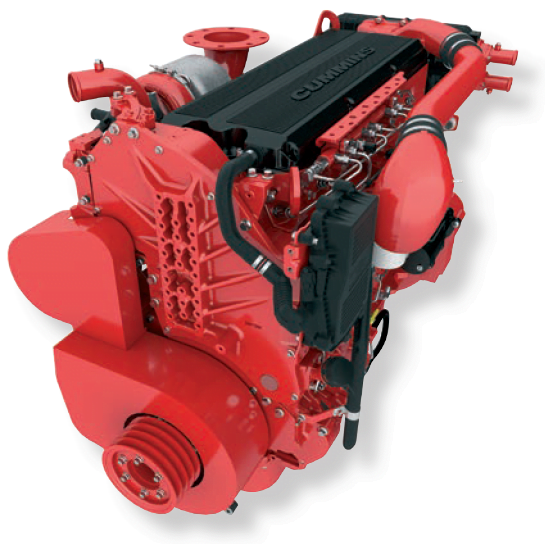

The Cummins SmartEfficiency initiative is a focused approach that improves uptime and reliability while providing a broad spectrum of reliable engine choices to meet every need. The combination of a low cost of operation, high reliability, clean operation and long-term durability are unsurpassed in the industry. The fact that all Cummins engines use the same control system technology and can be serviced at any authorized Cummins location ensures serviceability anywhere, anytime

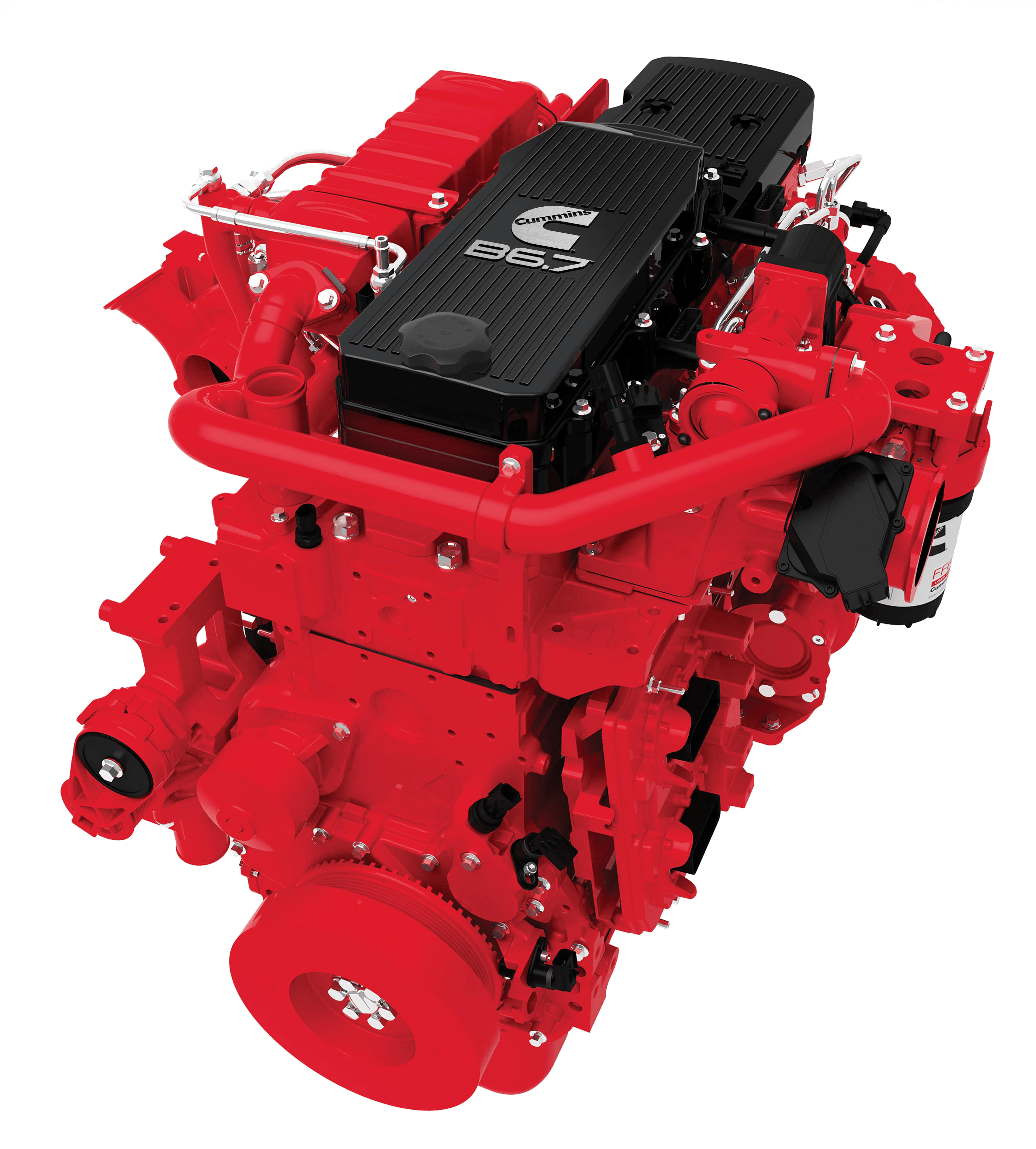

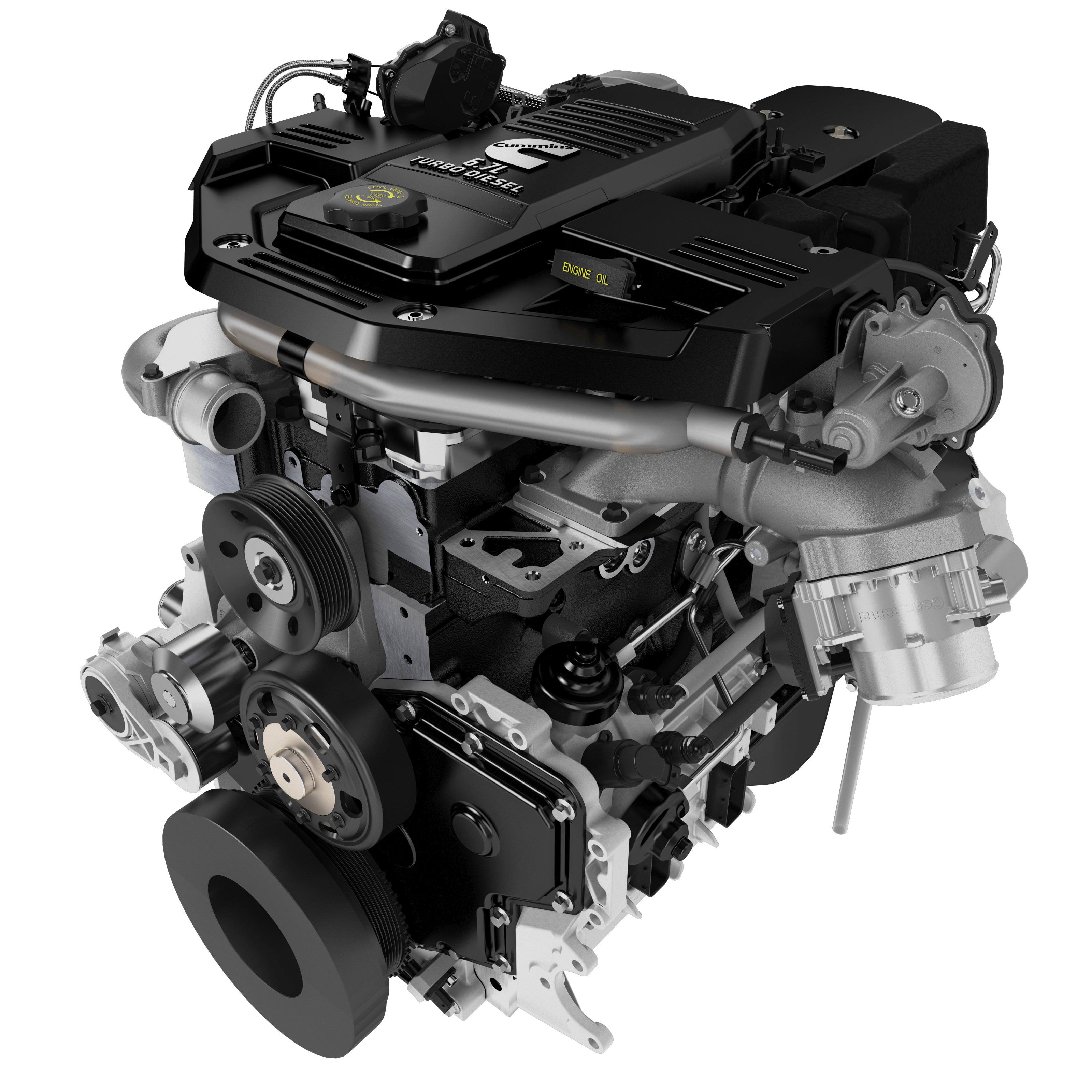

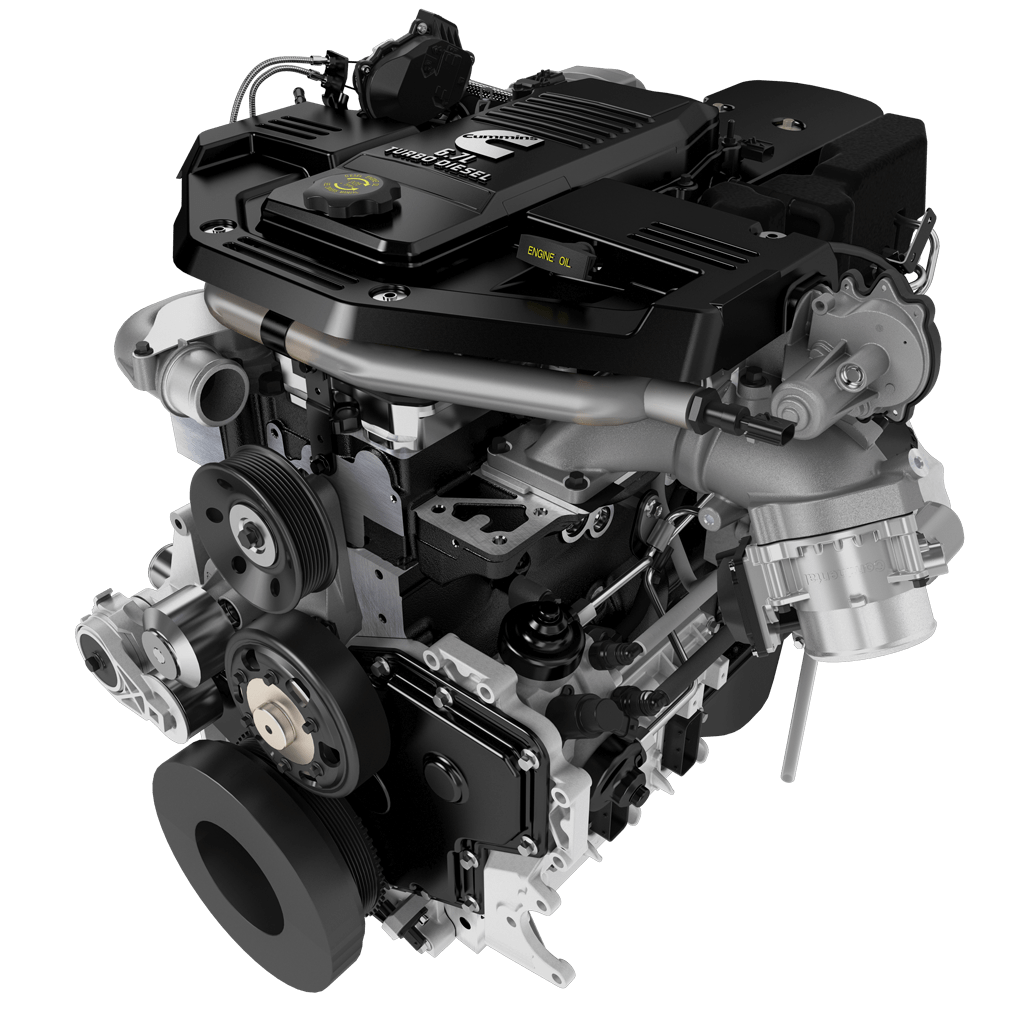

Even with a legacy of over 12 million B series engines sold over the last 32 years, we continue to keep improving a time-tested and proven reliable product. That’s why Cummins is redefining a classic and introducing the newest-generation B Series engine – the B6.7. The Cummins B6.7 for 2017 is more efficient, with up to 7 percent better fuel economy over the EPA 2013 ISB6.7. The B6.7 will have accumulated 1.5 million test miles in multiple real-world applications prior to its 2017 launch, ensuring exceptional uptime from the start. Plus, the 2017 B6.7 will be fully capable for the introduction of stop-start technology that will yield further improvements in fuel economy in stop-and-go duty cycles. That’s Cummins, SmartEfficiency – not just for the B6.7, but for an entire industry.

Aftertreatment Technology: Simply Better

The Cummins B6.7 diesel engine features a new Single Module™ aftertreatment system that sets the new standard for efficiency. It combines Selective Catalytic Reduction (SCR) and a Diesel Particulate Filter (DPF) into a single flow-through design. It occupies up to 70 percent less space and weighs up to 30 percent less. The smaller size allows it to be installed closer to the engine, for better heat management. That, together with the reduced weight, contributes to improved fuel economy. The UL2 Urea Dosing System eliminates the need for engine coolant lines to the doser, provides more efficient atomization, to minimize the risk of urea dosing deposits and reduces regeneration events, while maintaining a 3 percent to 4 percent Diesel Exhaust Fluid (DEF) usage factor.

Connected Diagnostics: Smarter Route Management with Connected Diagnostics

School bus drivers have enough to pay attention to without being concerned about engine fault codes. In the rare event that one is triggered while the bus is in operation, it can be diagnosed immediately over the air, through the addition of Connected Diagnostics. Cummins Connected Diagnostics delivers real-time engine fault code analysis, with a probable diagnosis and a recommended action for school buses that are equipped with telematics.

| Peak Torque | 520-660 lb-ft | 705-896 N*m |

| Governed Speed | 2600 rpm | |

| Clutch Engagement Torque | 400 lb-ft | 542 N*m |

| Number of Cylinders | 6 | |

| Engine Weight (Dry) | 1,150 Lbs | 522 Kg |

Cummins designs, develops and supports every component, from the air handling to the exhaust aftertreatment, to work as a totally integrated system – so we can optimize every function better than other engine manufacturers.

-

VGT Turbo from Cummins Turbo Technologies – This patented design is widely recognized as an industry performance leader. The refined design improves responsiveness in the B6.7 while an upgraded bearing system increases overall robustness. The VGT Turbo is a key element in providing increased fuel economy and exceptional braking horsepower

-

Connected Diagnostics™ – Wirelessly connect your engine to Cummins through a telematics device for immediate diagnosis of a fault alert. Within seconds, Connected Diagnostics provides a clear recommendation for continued operation or the need for service.

-

High Pressure Common Rail (HPCR) Fuel System – Delivers superior performance even in lower engine rpm ranges. Enables multiple injection events per cycle, for improved fuel efficiency with quieter, smoother operation.

-

Air Handling System – A more robust Exhaust Gas Recirculation (EGR) cooler and valve enhance thermal efficiency and reliability.

-

Single Module Aftertreatment From Cummins Emission Solutions – Combines high-efficiency SCR, a more reliable dosing unit and a DPF into a single flow-through unit. It is up to 70 percent smaller, so it’s easier to install, and as much as 30 percent lighter than the aftertreatment units it replaces. Better heat management improves fuel efficiency and minimizes periodic maintenance.

-

Fuel Filters And Lube Filters From Cummins Filtration – Fleetguard® filters protect against corrosion and contaminants with innovative NanoNet® technology. NanoNet media provides 10 times better protection than conventional fuel filters for lower cost of operation.

-

Single High-Capacity Electronic Control Module (ECM) – Offers higher capacity for faster processing of more information, fully integrated control over the engine and aftertreatment system for optimized performance and improved engine lamp strategy.

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

similar products

COMMERCIALQD 11HDKBN-6000C

Power

Torque

Certification

X15N (2024)

Power

400 - 500 hp

Torque

1450 - 1850 lb-ft

Certification

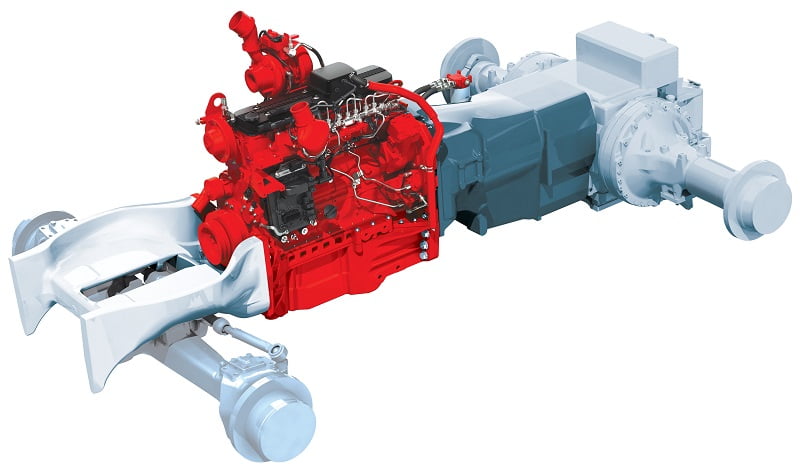

B6.7 Structural Engine

Power

155 - 326 hp

Torque

650 - 1014 lb-ft

Certification

EU Stage V, EPA Tier 4F

6.7L Cummins Turbo Diesel (2018) for Chassis Cab

Power

320 - 325 hp

Torque

650 - 750 lb-ft

Certification

EPA 2018

6.7L Cummins Turbo Diesel (2019) for Chassis Cab

Power

360 - hp

Torque

800 - lb-ft

Certification

EPA 2018

F4.5 Structural Engine

Power

130 - 160 hp

Torque

476 - 476 lb-ft

Certification

EU Stage V, EPA Tier 4F

Remanufactured Cummins Turbo Diesel

Power

325 - 385 hp

Torque

610 - 930 lb-ft

Certification

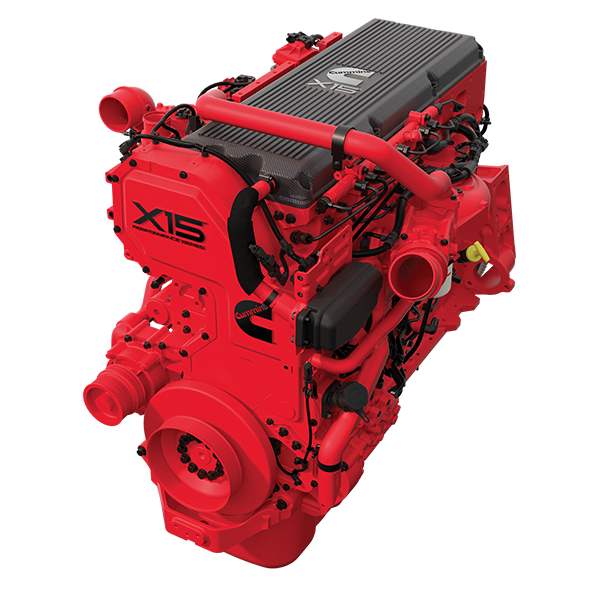

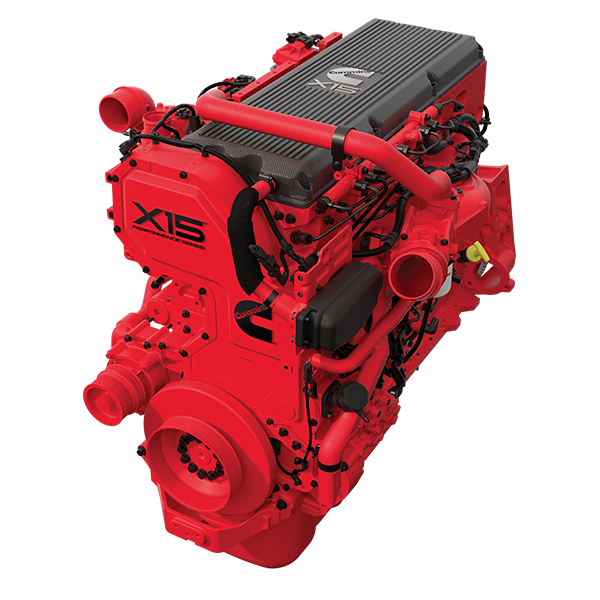

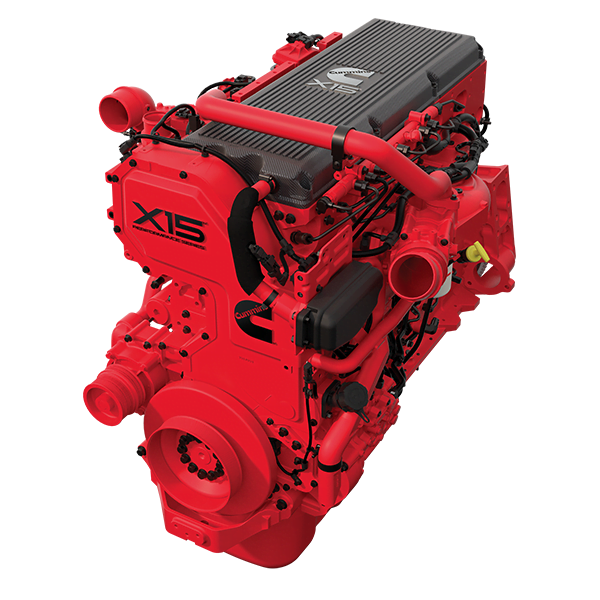

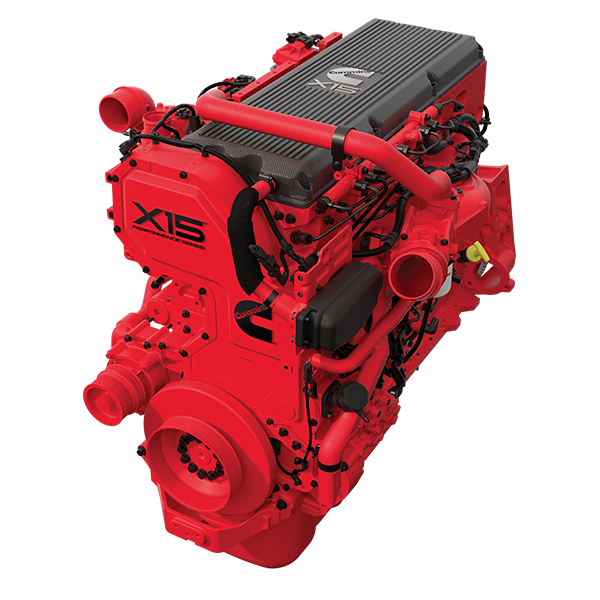

X15 Performance Series (2017)

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

X15 Performance Series for Heavy-Duty Truck (2017)

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

X15 Performance Series for Fire & Emergency (2017)

Power

505 - 565 hp

Torque

1850 - 1850 lb-ft

Certification

EPA 2017

X15 Performance Series for TEMs & Body Builders

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

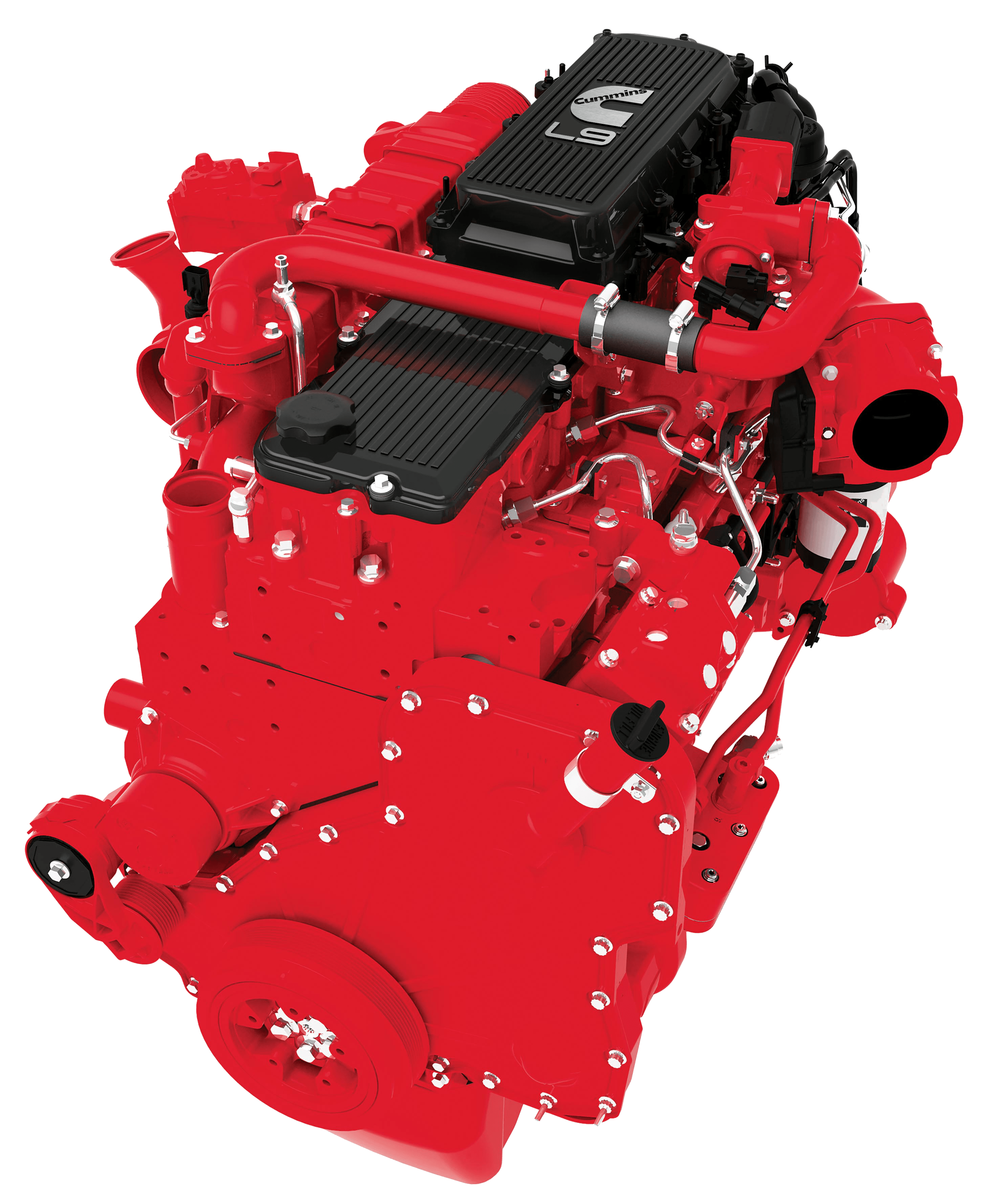

L9 for Shuttle Bus (2017)

Power

260 - 380 hp

Torque

720 - 1250 lb-ft

Certification

EPA 2017

X15 For Motorhomes (2017)

Power

565 - 605 hp

Torque

1850 - 1950 lb-ft

Certification

EPA 2017

X15 (Stage V)

Power

450 - 675 hp

Torque

1600 - 2050 lb-ft

Certification

EU Stage V