Genuine VS. Non-Genuine Parts

We’ve tested and compared the results: Cummins parts perform better and last longer. When it comes to productivity, efficiency, uptime and profitability, there is a genuine difference.

The Risk of Using Non-Genuine Parts

Competitive part manufacturers may try to reverse engineer Cummins parts and build something that will fit like an original part at a cheaper price. Using non-genuine parts which don’t meet critical engineering design specifications can impact:

- Engine Performance

- Fuel Economy

- Reliability

- Durability

- Uptime

- Warranty

Non-genuine put to the test

Cummins Engineers conducted lab analysis and destructive testing on over 300 nongenuine overhaul kit components for Cummins on highway engines, including pistons, piston rings, piston pins, cylinder liners, main bearings, connecting rod bearings, head gaskets and injectors. Of the over 300 non-genuine parts tested, none met all of Cummins Design Specifications.

The Genuine Difference

300+

non-genuine overhaul kit components tested through lab analysis and destructive testing

0

non-genuine parts met all of Cummins design specifications

100+

years of perfecting the design and manufacturing of Genuine Cummins parts

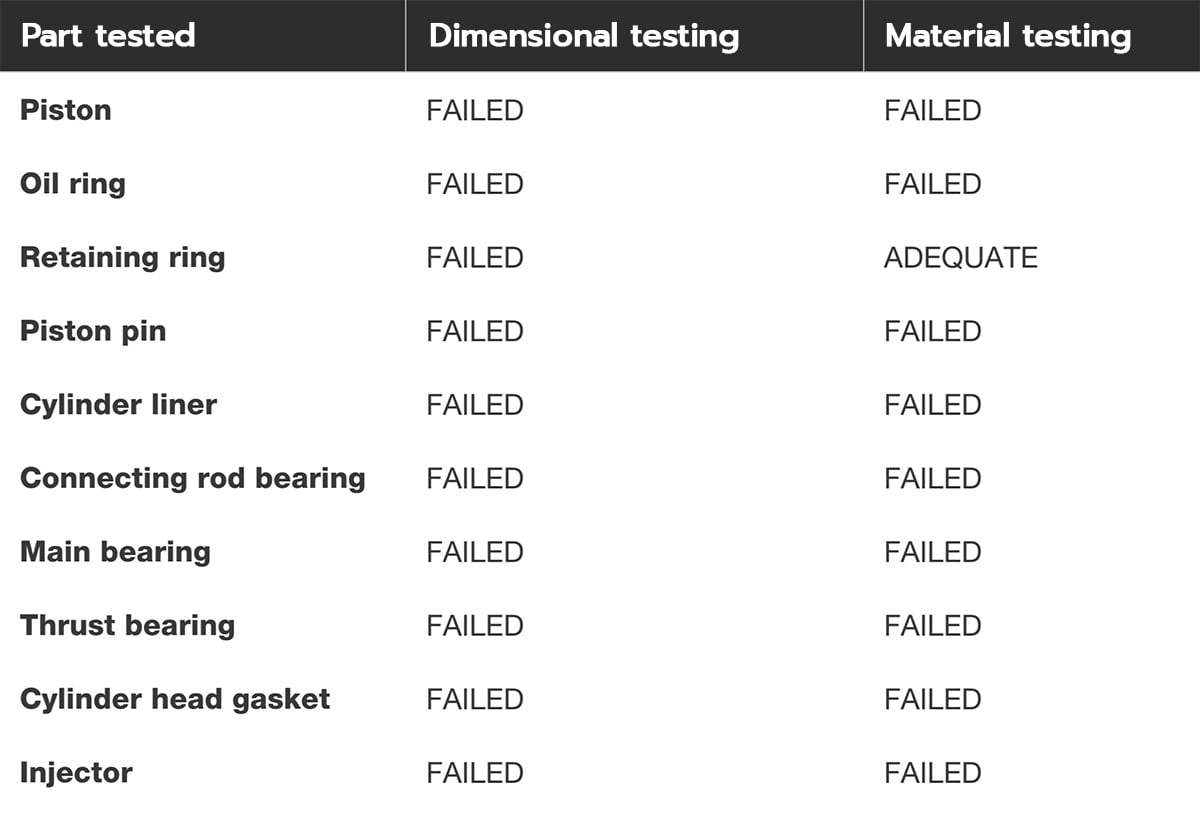

NON-GENUINE PART INSPECTION RESULTS

Of the over 300 non-genuine parts tested, none met all of Cummins Design Specifications, and most failed in both the dimensional and material testing categories. Test results marked as “adequate” marginally met Cummins design intent, indicating that it loosely met some of Cummins design specifications, but not all of them.

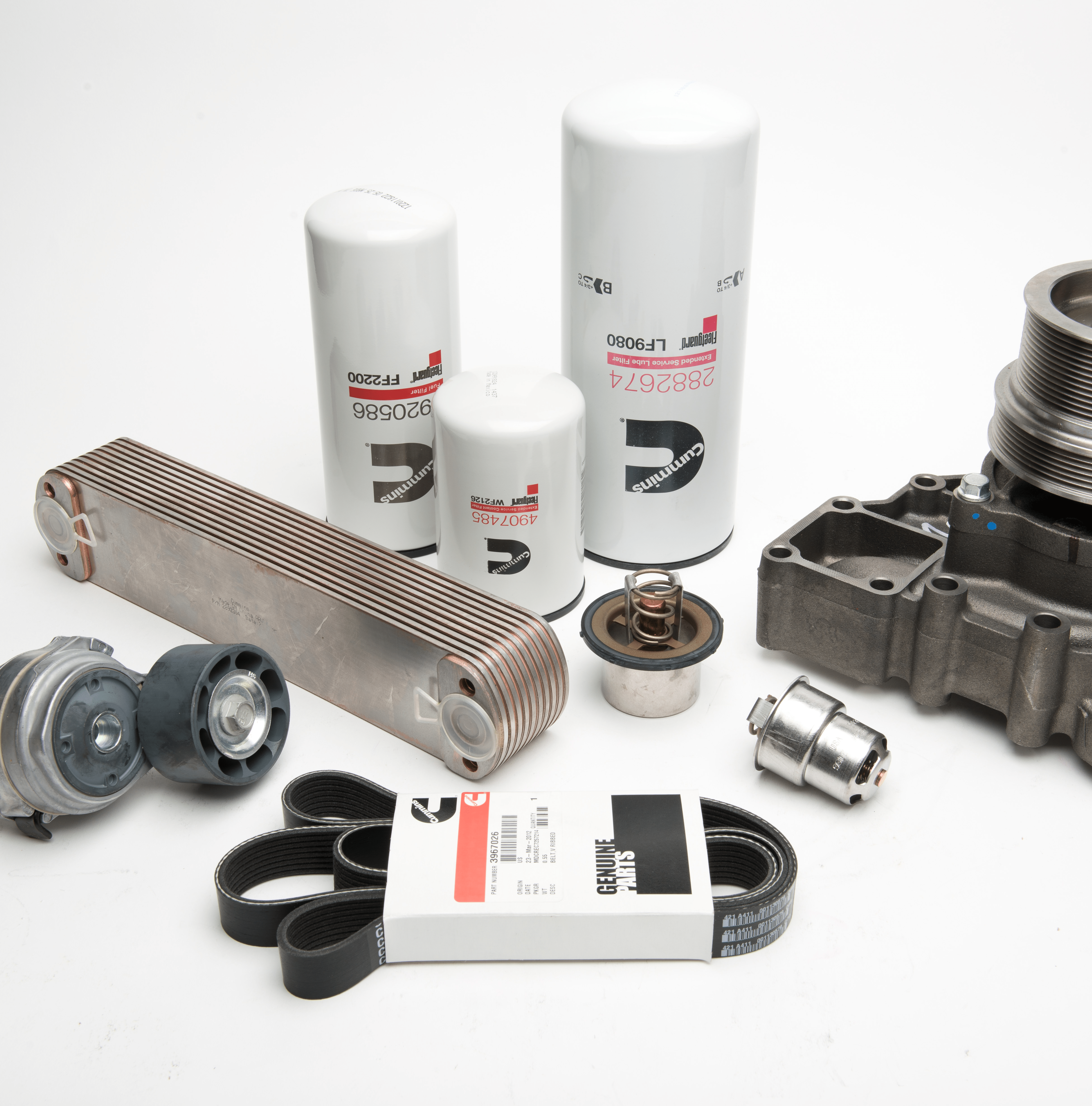

SAVING A LITTLE COULD ULTIMATELY COST YOU:

Early life failure

Downtime

Non-warranty repair cost

Additional fuel cost

Progressive damage to aftertreatment

Catastrophic failure

Buy Cummins genuine components and parts from us only. Contact Cummins DKSH (Thailand) today by calling +662-301-7500 or click the button below