PRODUCT Detail

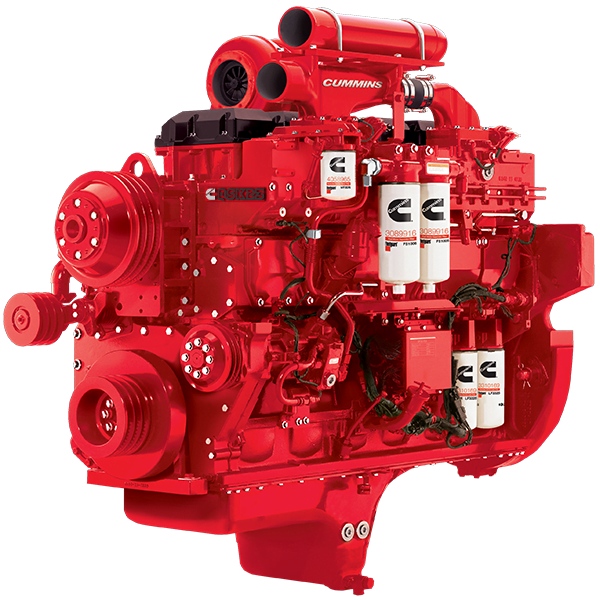

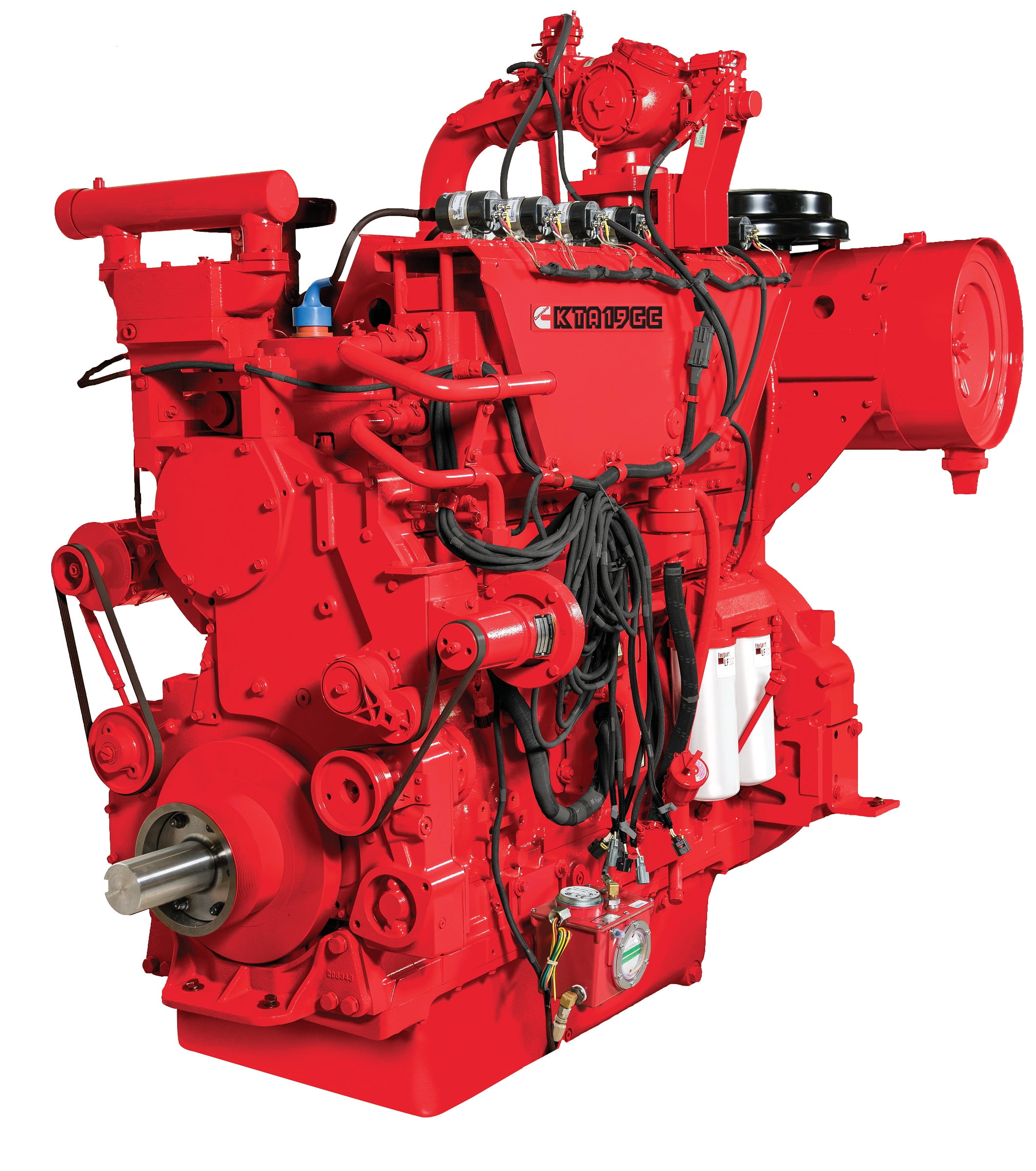

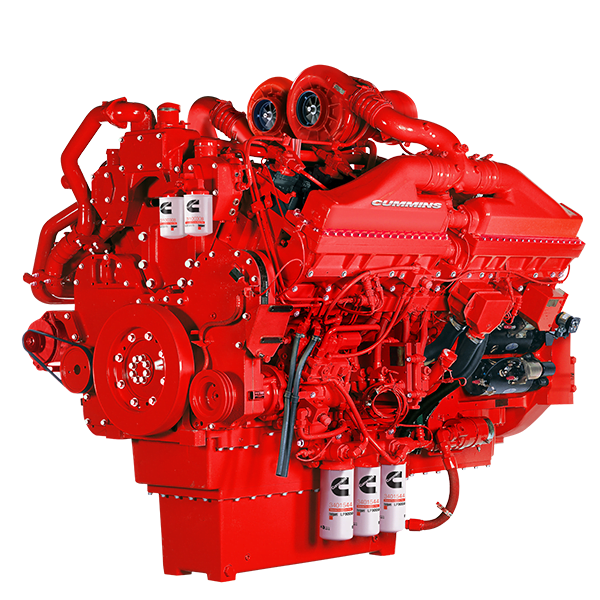

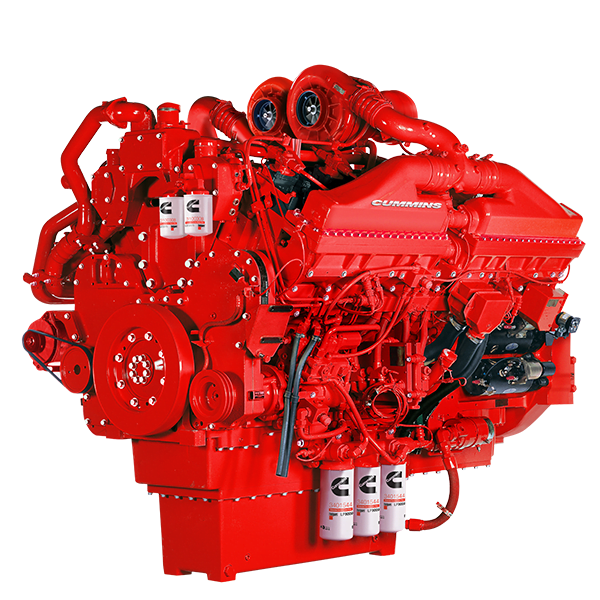

Gathering compression applications require power that is reliable, durable and has world class support. It calls for the Cummins KTA19GCE – an emissions compliant capable, high-performance natural gas engine that shares the proven heritage of the Cummins K Series diesel engines and many of the same heavy-duty components. It is no surprise that the KTA19GCE has low maintenance cost, stays emissions compliant and keeps the gas flowing. Every day.

General Specifications

Inline 6-Cylinder, 4-Cycle, Natural Gas

| Bore | 6.25 in (159 mm) |

| Stroke | 6.25 in (159 mm) |

| Displacement | 18.8 L (1150 cubic in) |

| Engine Power* | 380 hp, 420 hp (283 kW, 313 kW) |

| Compression ratio | 8.5:1 |

| Aspiration | Turbocharged and aftercooled |

| Exhaust Type | Watercooled manifold |

| Weight** | 4840 lb (2195 kg) |

| Lube oil capacity | 27.0 gal (102.0 L) |

| Rotation (Facing Flywheel) | Counterclockwise |

* Rating dependent

** Weight is approximate and varies with options.

Engine Technical Data

| Model | KTA19GCE | |

| Curve Number | FR-4764 | |

| Output Power (1) 100% 75% |

HP (kW) HP (kW) |

420 (313) 315 (235) |

| Engine Speed 100% Max Turn Down |

RPM RPM |

1800 1350 |

| Aftercooler Water Inlet Temperature | °F (°C) | 130 (54.4) |

| Compression Ratio | 8.5:1 | |

| Emissions Data – Engine-Out Emissions (1) NOx CO VOC |

g/hp-hr (ppm) g/hp-hr (ppm) g/hp-hr (ppm) |

12.9 (3177) 11.6 (4683) 1.26 (715) |

| Fuel Consumption (1) 100% 75% |

BTU/hp-hr (MJ/kW-hr) BTU/hp-hr (MJ/kW-hr) |

7967 (11) 8498 (12) |

| Heat Rejection (1) Jacket Water Aftercooler Exhaust |

BTU/min (kW) BTU/min (kW) BTU/min (kW) |

16,265 (286) 1304 (23) 17,280 (304) |

| Exhaust System (1) Flow Rate Stack Temp Max Back Pres. |

ft3/min (L/s) °F (°C) in-Hg |

2126 (1003) 1347 (731) 2 |

| Intake System (1) Flow Rate Max Restriction |

ft3/min (L/s) in-H2O |

604 (285) 15 |

| Gas Pressure | Min – Max psi | 15 – 30 |

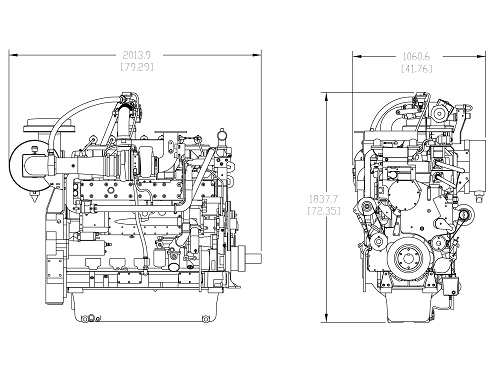

General Dimensions

| Length | Inches (mm) | 79.3 (2014) |

| Width | Inches (mm) | 41.8 (1061) |

| Height | Inches (mm) | 72.4 (1838) |

*Dimensions are approximate and vary with options.

Disclaimers

(1) All data is based on the engine operating with fuel system, water pump, and 6 in H2O (1.49 kPa) inlet air restriction with 3 in (76 mm) inner diameter, and with 1 in Hg (3 kPa) exhaust restriction with 3 in (76 mm) inner diameter; not included are alternator, fan, optional equipment and driven components. Coolant flows and heat rejection data based on coolants as 50% ethylene glycol/50% water. All data is subject to change without notice.

Designed for the gas compression market, the KTA19GCE delivers exceptional reliability and low cost of operation.

Base Engine – Most major components, including block, crank, cam, gears and liners are common with the proven K19 diesel. Common gas unique components on the KTA19GCE and GTA38GCE lower your operating cost.

Emissions – 2011 NSPS Compliant Capable (1/2/.7 NOx/CO/VOC), Factory Supplied AFR, FW Murphy Supplied RB Emissions Kit, 0.5g NOx Capable (Consult Factory).

Air/Fuel Ratio Control – Direct-acting Electronic Pressure Regulator Assembly controlled by engine specific calibration provides reliable emissions control.

Air Handling – Turbocharger design delivers maximum performance and life. It includes factory-installed heavy-duty air cleaner.

Speed Control – Integrated electronic governor provides stable rpm control with optional input to monitor and control suction or discharge pressure.

Ignition System – EICS™ capacitive discharge ignition with smart-coil technology provides reliable spark and individual cylinder diagnostics and knock sensing capabilities.

Lubrication System – Deep, full-length, high-capacity oil pan. Combination full-flow and bypass oil filters reduce maintenance costs while extending service intervals.

Flywheel and flywheel housing – SAE 0, cast iron, including provisions for one 5/8-18 and two 3/4-16 magnetic pickups, machined to accommodate starter mounting.

Power Take-Off (PTO) – Front stub shaft options are offered for driving the compressor cooler fan.

Starting system – The standard system features a robust Delco Remy® 39MT 24-volt starters with SAE #3 mounting flanges. An air/gas starter is optional.

Electrical system – Includes a 24-volt alternator.

Cooling system – A two-pump/two-loop cooling system effectively separates the aftercooler and jacket water coolant circuits to maintain lower intake manifold temperatures and providing capability for higher power ratings. Integrated coolant filters add corrosion protection for the jacket water circuit.

Exhaust system – The water-cooled manifolds reduce surface and exhaust gas temperatures.

Warranty – Cummins one year, unlimited hours. Backed by a worldwide distributor network.

Standard Equipment

Digital Display (Optional)

- AFR system status

- Engine fault codes with history

- Warning and shutdown information

- User interface eliminates need for laptop for engine adjustment or commissioning

- Ignition display

Safety Shutoff Protection

- Intake manifold temperature

- Intake manifold temperature change rate

- Intake manifold pressure

- Overspeed

- ECM temperature

- O2 sensor out of range

Mounting Arrangement

- Four-point mounting on structural oil pan

- Mounting feet designed for use with Vibracon ® chocks

- Lift provisions on engine

Power Take-off

- Front stub shaft

Download brochures

Register Cummins products to get up to date information on your repairs, products details

technical support and much more

similar products

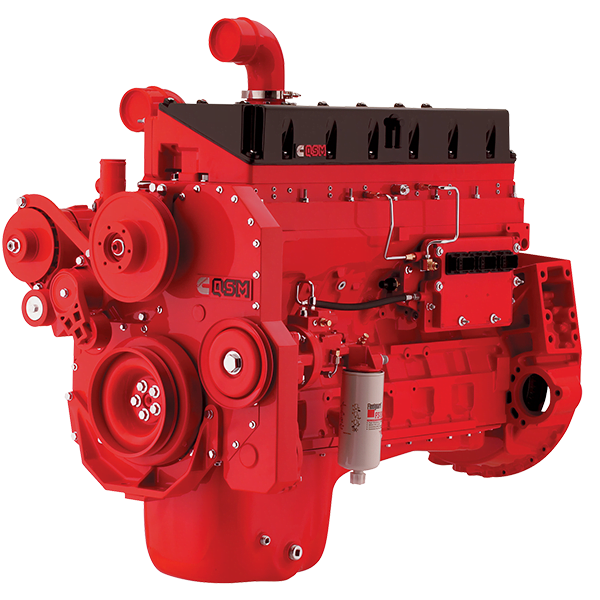

KTAA19 for Commercial Industrial

Power

-

Torque

-

Certification

N/A

KTAA19 for Commercial Industrial

Power

-

Torque

-

Certification

N/A

GTA8.3G for Commercial Industrial

Power

-

Torque

-

Certification

N/A

GTA8.3G for Commercial Industrial

Power

-

Torque

-

Certification

N/A

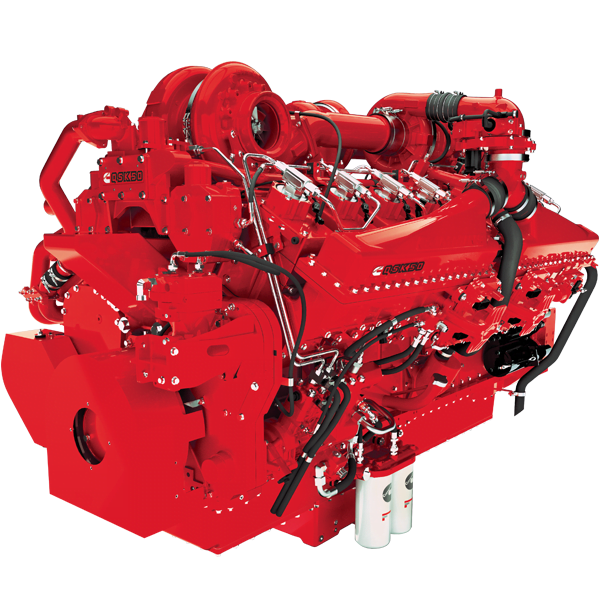

QST30 for Oil & Gas

Power

1200 - 1500 hp

Torque

3750 - 4877 lb-ft

Certification

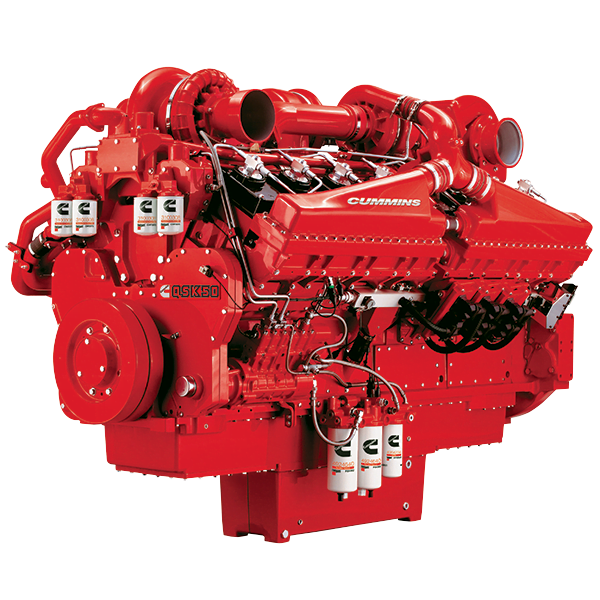

QSK50 Dual Fuel for Well Servicing

Power

2250 - 2500 hp

Torque

-

Certification

EPA Tier 2, EPA Tier 4

QSK50-DPM Tier 2/CSIII

Power

1450 - 1450 hp

Torque

-

Certification

EPA Tier 2

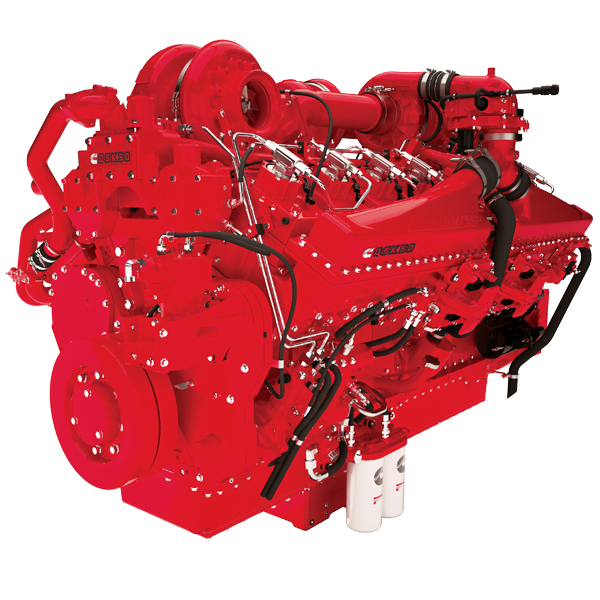

QSK50 Well Servicing Applications

Power

2000 - 2500 hp

Torque

5805 - 7081 lb-ft

Certification

EPA Tier 2, EU Stage I

QSK60 for Oil & Gas

Power

-

Torque

-

Certification

EPA Tier 1

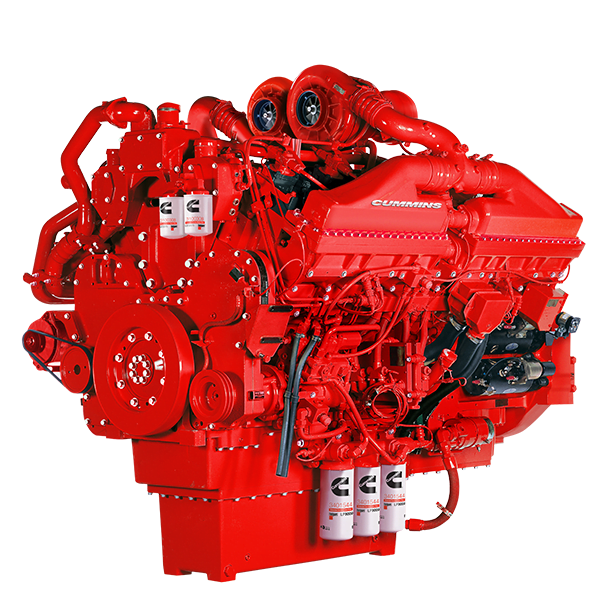

QSK50 for Well Servicing (Tier 4 Final)

Power

2250 - 2500 hp

Torque

6299 - 7080 lb-ft

Certification

EPA Tier 4, EU Stage I

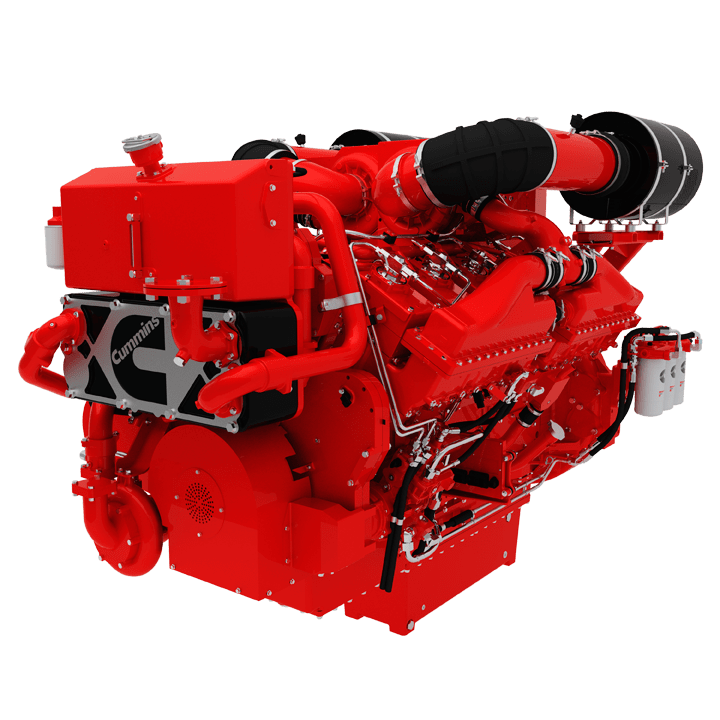

QSK50 for Drilling

Power

1400 - 1600 hp

Torque

4707 - 5041 lb-ft

Certification

EPA Tier 2, EU Stage I

QSK38 for Drilling

Power

920 - 1260 hp

Torque

-

Certification

EPA Tier 2, EU Stage I

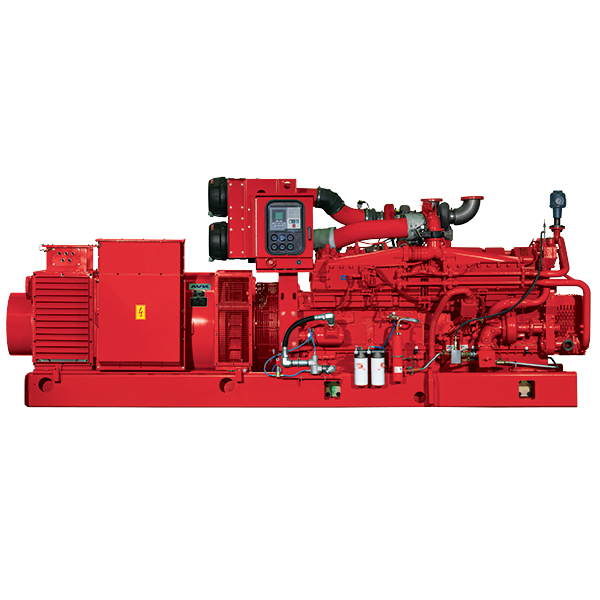

QSK38 Land-Based Power Module for Drilling

Power

1034 - 1034 hp

Torque

-

Certification

EPA Tier 2, EU Stage I

QSK38 Well Servicing Applications

Power

920 - 1260 hp

Torque

3591 - 4590 lb-ft

Certification

EPA Tier 2, EU Stage I